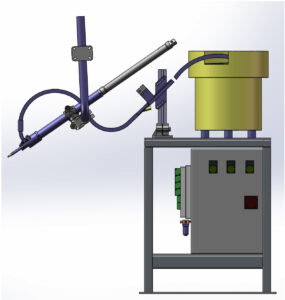

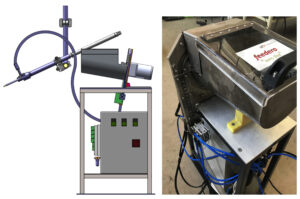

Automatic Nut and Bolt Feeder Machines

- It is an equipment that can be easily integrated into spot and projection welding machines.

- As in the traditional nut welding method, the era of first holding the sheet metal part on the lower electrode with one hand, then bringing the nut with the other hand, centering it using the “move-eye-pin” method, and carefully pressing the pedal to avoid moving the parts has ended.

- The welding operator only brings the sheet metal part to be welded with a nut between the studs and presses the pedal. After this point, which is the placement of the welding nut and the closing of the electrodes, and the supply of the welding current, is automatic.

- Nuts filled into the device’s vibratory hopper using the “pouring” method are conveyed to the “feeding head” with the welding nozzle tips always facing downwards. When the pedal of the welding machine is pressed, these nuts are attached to the centering pin on the lower electrode by the chameleon’s tongue. The electrodes close and the welding process ends.

- Two or three nut feeders can be connected to the same welding machine.